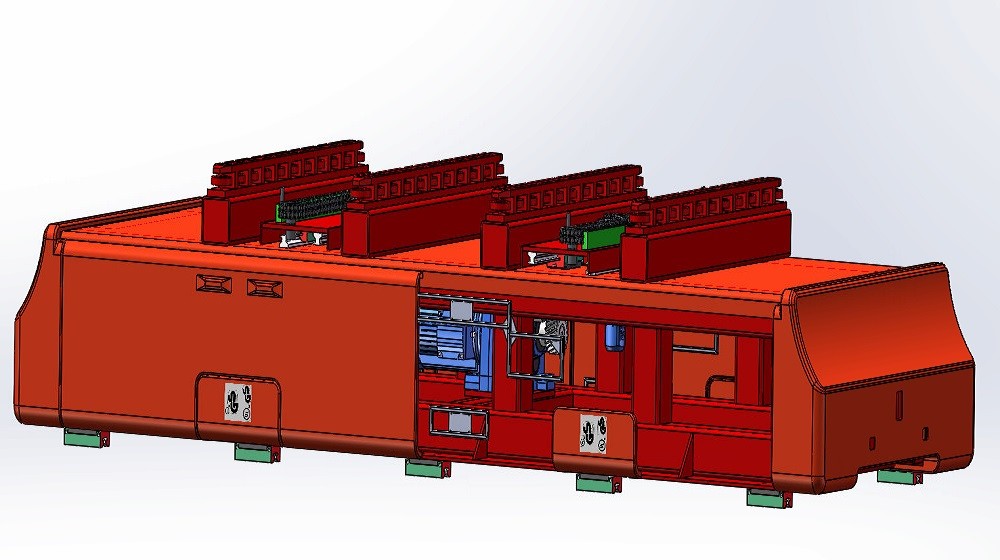

Intelligent Stacked Automated ASRS-RGV

The main body of an automated three-dimensional warehouse consists of shelves, roadway type stacking cranes, entry (exit) workbenches, and automatic transportation (exit) and operation control systems.

RGV, also known as Rail Guided Vehicle, is an English abbreviation for Rail Guided Vehicle. RGV cars can be used for material turnover between various three-dimensional warehouses and conveyor lines. The car passage can be designed to be of any length, which can improve the overall efficiency of the warehouse. Moreover, there is no need for forklifts to enter the tunnel during operation, making it safer.

Features:

Firstly, it can be divided into two types according to its function: assembly type RGV and transportation type RGV, mainly used for material transportation, workshop assembly, etc;

Secondly, according to the mode of motion, it can be divided into circular track type and linear reciprocating type. The circular track type RGV system has high efficiency and can work with multiple vehicles at the same time. The linear reciprocating type generally only has one RGV, which performs linear reciprocating motion and has relatively low efficiency compared to the circular RGV system.

The characteristics of RGV cars are: fast acceleration and movement speed, suitable for transporting heavy workpieces; Due to the fixed guide rail, the walking is stable and the parking position is relatively accurate; The control system is simple, reliable, low in manufacturing cost, and easy to promote and apply; The walking route is inconvenient to change, and the turning angle should not be too small;

RGV can connect multiple logistics nodes, with the characteristics of fast, simple configuration, and easy maintenance. In some logistics solutions, it can replace conveyor systems with relatively complex configurations and poor mobility; According to different logistics scales and frequencies, the system can select multiple RGVs to operate simultaneously to meet practical requirements;

The control of RGV is completed by its scheduling control system; If the logistics path and working mode are changed, it can be achieved by resetting the relevant parameters of the control system.

Advantages of RGV cars: RGV cars can be used in warehouses with various high-density storage methods. The car passage can be designed to be of any length, which can increase the storage capacity of the entire warehouse. Moreover, there is no need for forklifts to enter the lane during operation, making it safer. By utilizing the advantage of forklifts that do not require entry into the roadway, coupled with the rapid operation of small cars in the roadway, the operational efficiency of the warehouse is effectively improved.

QDITC was founded in 2015 and is located at Shushan District, Hefei City,China. The main products include the integration of automated warehouse such as VLM(Vertical Lift Machine && Storage System), VCM (Vertical Carousel Machine && Storage System), VSM (Vertical Sorting Machine && Storage System),IHSM( Intelligent Horizontal Sorting Machine && Storage System), Intelligent Smart Stacking Warehouse (Smart AS/RS), AGV/RGV, etc.

Our products are widely used in manufacturing, trade, logistics, and terminal enterprises and institutions. With the prominent advantages of "faster, more accurate, and more dense", they can save more than 90% of storage space ,and increase efficiency by 3x. They can be applied to the entire storage and zero retrieval process of manufacturing enterprise line warehouses, large capacity storage and sorting of trade enterprises, small material storage, transportation, and sorting of logistics enterprises, and can also be applied to large capacity storage, intelligent sorting ,and automate management.

Our Products have significant features of fast implementation, flexible deployment, and easy relocation, providing customers with cost-effective "storage, transportation, picking, and management" material solutions.

Company&Factory display

Workshop show

Equipment display

INQUIRY

Categories

Latest News

Contact Us

Contact: Mr.Miao

Phone:

E-mail: miaocp@qdquick.com

Whatsapp:

Add: No. 1499 Zhenxing Road, Shushan District, Hefei City, Anhui Province, China