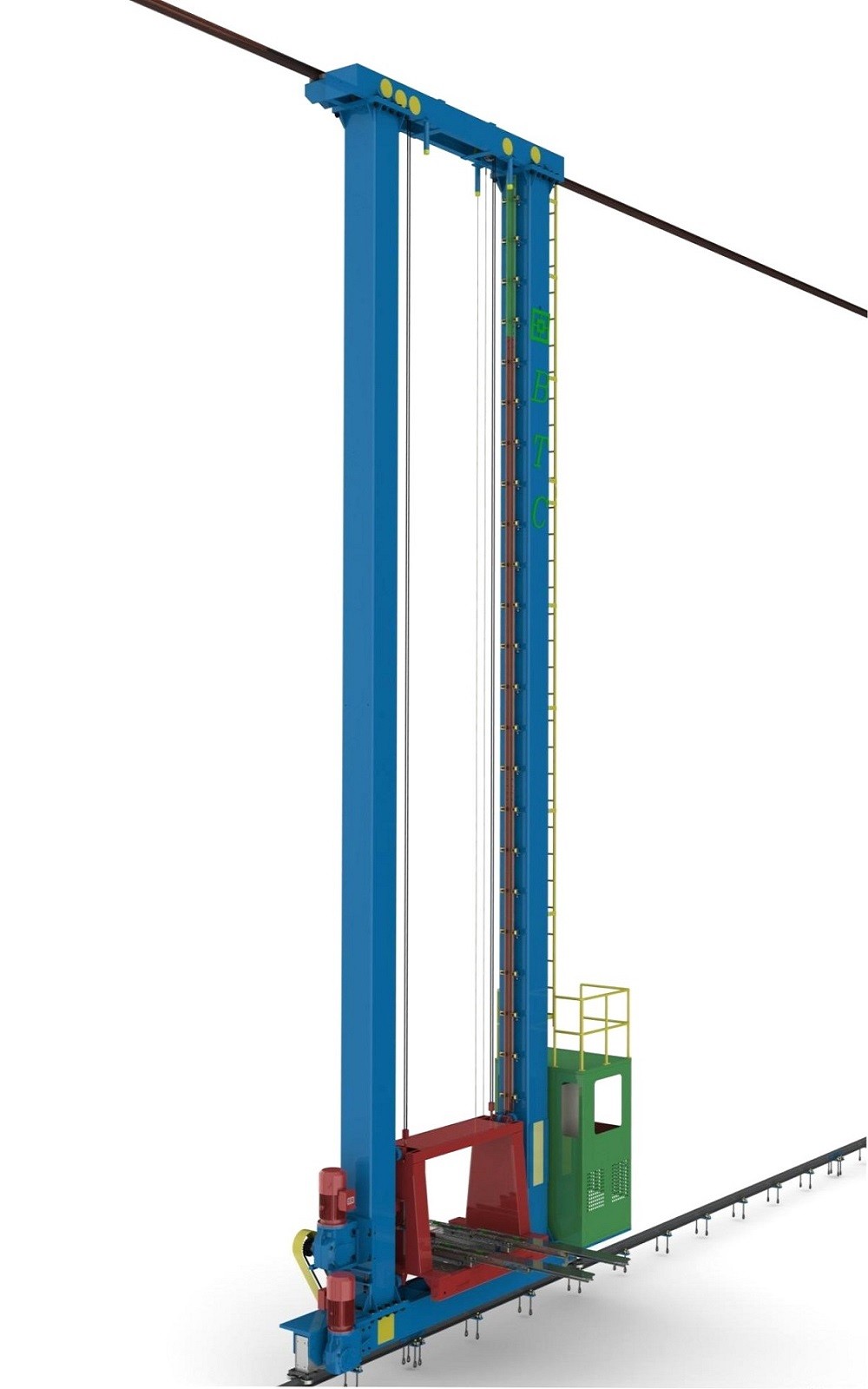

Intelligent Stacked Automated ASRS-Stacker

The main body of an automated three-dimensional warehouse consists of shelves, roadway type stacking cranes, entry (exit) workbenches, and automatic transportation (exit) and operation control systems.

Stacking crane (English name: AS/RS), also known as stacking crane, refers to a specialized crane that uses forks or crossbars as pick-up devices to grab, transport, and stack unit goods in warehouses, workshops, or from high-rise shelves. It is a storage equipment.

Features:

1. High work efficiency

Stacking crane is a specialized equipment for three-dimensional warehouses, with high handling speed and cargo access speed. It can complete inbound and outbound operations in a short time, and the maximum operating speed of the stacking crane can reach 500m/min.

2. Improve warehouse utilization

The stacker crane has a small size and can operate in narrow tunnels. It is also suitable for high-rise shelf operations and can improve warehouse utilization.

3. High degree of automation

The stacker crane can be remotely controlled, and the operation process does not require manual intervention. It has a high degree of automation and is easy to manage.

4. Good stability

Stacking cranes have high reliability and good stability during operation.

Operation mode:

The shelf system using a stacker crane should be numbered according to the location of the columns, layers, and rows of the shelves, in order to automatically enter and exit the warehouse to the designated location and facilitate the use of electronic computers for in warehouse management. In fact, most of the latest large-scale three-dimensional automated warehouses use electronic computers for in warehouse management. However, in order to save equipment investment, most small automatic warehouses still use manual control and semi-automatic control.

1、 Manual control

Manual control refers to the driver checking the cargo location number on the driver's desk of the stacking crane while operating the joystick or button to complete walking, lifting, and forking in and out.

2、 Semi-automatic control

The driver presses the button for the required cargo location number on the driver's desk of the stacking crane, and the crane automatically completes various movements such as walking and lifting, and stops at the designated cargo location number. The movement of the cargo fork in and out is controlled by a manual joystick or a button. The return action is mostly to automatically return to the original position by pressing the return button.

3、 Fully automatic control

This is a form of unmanned operation, where the control panel is installed outside the crane and uses buttons or punch cards as instructions. Therefore, as long as the start button is pressed, the stacking crane can be remotely controlled to automatically enter and exit the warehouse. Recently, there have also been methods of using magnetic core storage devices and other storage devices to store the inventory or variety of each cargo location number for in stock management.

4、 Computer control

Set up a ground control panel directly connected to the electronic computer, input the inbound and outbound instructions into the electronic computer for centralized control. The instructions for entering and exiting the warehouse issued by the electronic computer are stored in a front box calculator on the ground control panel. The calculator controls the stacking crane to automatically enter and exit the target goods, and performs calculations on the location number, variety, and frequency of entering and exiting the warehouse, implementing in warehouse management.

In large three-dimensional automated warehouses, this management method is often adopted. In the small independent shelf style warehouses that have been built, there are also some that use small electronic computers for in warehouse management.

QDITC was founded in 2015 and is located at Shushan District, Hefei City,China. The main products include the integration of automated warehouse such as VLM(Vertical Lift Machine && Storage System), VCM (Vertical Carousel Machine && Storage System), VSM (Vertical Sorting Machine && Storage System),IHSM( Intelligent Horizontal Sorting Machine && Storage System), Intelligent Smart Stacking Warehouse (Smart AS/RS), AGV/RGV, etc.

Our products are widely used in manufacturing, trade, logistics, and terminal enterprises and institutions. With the prominent advantages of "faster, more accurate, and more dense", they can save more than 90% of storage space ,and increase efficiency by 3x. They can be applied to the entire storage and zero retrieval process of manufacturing enterprise line warehouses, large capacity storage and sorting of trade enterprises, small material storage, transportation, and sorting of logistics enterprises, and can also be applied to large capacity storage, intelligent sorting ,and automate management.

Our Products have significant features of fast implementation, flexible deployment, and easy relocation, providing customers with cost-effective "storage, transportation, picking, and management" material solutions.

Company&Factory display

Workshop show

Equipment display

INQUIRY

Categories

Latest News

Contact Us

Contact: Mr.Miao

Phone:

E-mail: miaocp@qdquick.com

Whatsapp:

Add: No. 1499 Zhenxing Road, Shushan District, Hefei City, Anhui Province, China